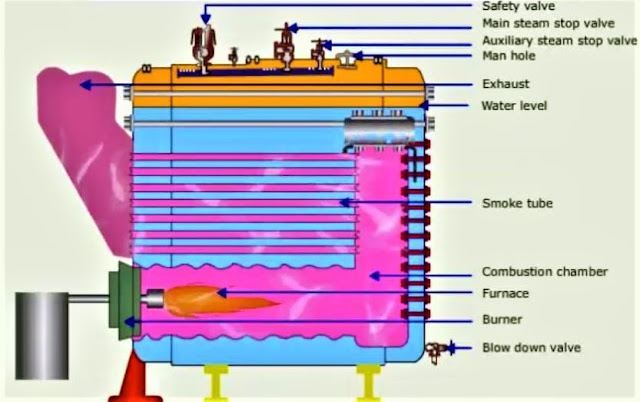

Maintenance of auxiliary smoke tube boiler (Donkey boiler)

Following are the maintenance activities carried out on the auxiliary smoke tube boilers.

- Cleaning the water and gas sides; waterside is brushed cleaned, checked for cracks and erosion.

- The grease/dirt is "scum-blown" from the boiler water surface.

- The waterside may be found to be having substantial scale deposits, which cannot be cleaned mechanically, need to be "bolled out".

- The boiler is then filled to the normal water level through the manhole with a solution of trisodium phosphate (Na3PO4) as per the guidelines of the manufacturer.

- Then the boiler is fired very slowly to its working pressure and so maintained (i.e., bank fired) for about 2 hours, with the main steam stop valve shut.

- Then the firing is stopped and slowly the boiler is finally shut-down and blown down by using the blow-down valve.

- The water space should then be washed/brushed clean for removing the remnant chemicals/scales.

- The gas (smoke) side cleaning can be carried out by blowing-in alkaline water or steam through their insides, in case, the most effective method of manual cleaning by tube-brushes is not feasible.

- The mountings / external fittings should be checked and serviced properly.

- Cleaning and checking the burner equipment including the flame detector, burner nozzle, fuel-oil supply system, electrodes etc.

No comments